I built it.

It uses T-nuts to hold in the T-slots of the table. Two 1/4"-20 thumbscrews control X and Y of the 3/8" steel rod that allows me to get every workpiece in the same position. This lets me avoid using the edge finder each time. Also, if I am trying to cut two pieces to the same length, I can cut one to length and be sure the next one ends up the same length.

On the first try, I for reason that I can remember decided to use 2" long 10-32 thumbscrews. (The Sherline's standard T-nuts are 10-32.) That was way too long.

I ordered some 1" long SHCS screws and they were a little short for a 1" thick block, so I couinterbored the top of the block 0.3" deep and that was just enough.

This was partly to have a flat surface for the thumbscrews to grab. This reduces rotation and also allows me to keep the various parts at right angles.

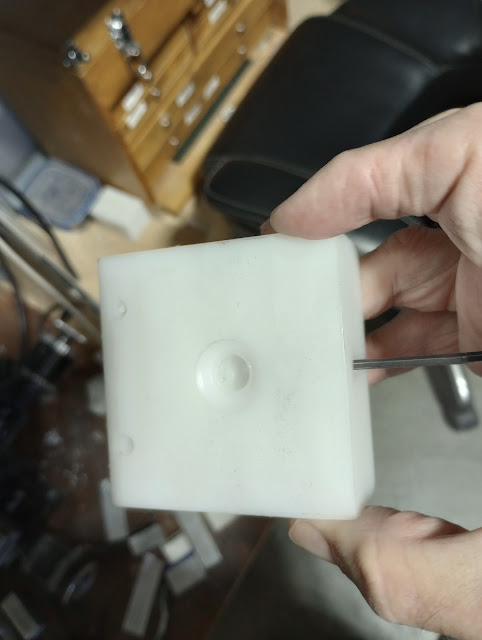

The bottom block has a 3/8" hole milled .75" deep into a 1" thick block and a tiny setscrew locking the rod in place.

Why does the hole seem to be countersunk? I tried to mill at too high a rate and the acetal melted into a blob that excavated a molten hole.

What's left. The top block should be wider so the horizontal bar is more centered in the mill vise; the top rod should be longer to handle workpieces farther right in the mill vise.

Milling the flat on those steel rods was slow, especially compared to acetal. But I wrote some gCode to remove .01" per pass and just let it run unatended for several hours. It ran to completion just fine.

No comments:

Post a Comment