I am converting 3" OD, 0,5" ID .5" thick steel donuts into a counterweight for an EQ1 telescope mount. The current plan is to epoxy four together to make a 2 kg weight. I picked the 3" diameter because it fits into my 3" 3-jaw chuck. I can face them just fine, but turning the edge to get a pretty and consistent finish? Typically you open jaws inside the interior hole, but neither of my chucks can go small enough for a 0.5" hole.

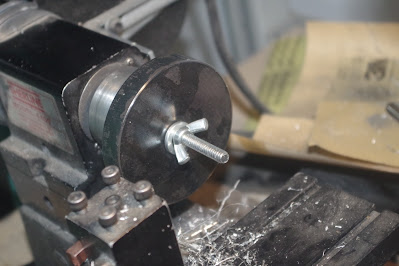

The headstock is 3/4"-16 threaded. Some years for ScopeRoller, I made a couple of these for holding 3/8"-16 workpieces very securely--more so than a chuck can tightly hold slippery acetal.

My first feeble attempt was to tap a 1/4"-20 hole through and then use a 1/4"-20 bolt with a washer and nut to lock the donut in place. It would not hold.

So I turned the holder to .497" diameter, just slightly smaller than the inside of the donut. It is not a press fit, but tight enough to turn the edge.

Next step. Tommy bars (I am not sure just Sherline calls then that) go into .15" diameter holes in the chucks to loosen them when on tightly. So I put the workpiece holder on the rotating table on the tilting table at 90 degrees. Then I drilled three tommy bar holes 120 degrees apart.

This required finding the center of the workpiece left and right and the center. This was easier than I expected.

The correct final steps involve using a center drill to mark the drill spot. (Center drills do not twist or get lost like twist drills.) The chuck was too large to get the center drill that close. Fortunately, aluminum is so soft that the twist drill went right in. This was .3 inches/min.

Rotate 120 degrees each time; three perfect tommy bar holes.

I managed to turn four of the six donuts before running out of steam. I will do the rest, then dri; and tap the thumbscrews for two of the weights tomorrow.

No comments:

Post a Comment